BLOG

Electric terminals at BIBUS France

Rather than doing nothing about environmental problems because we feel powerless or think that the solution must come from others, we can all take action at our own level by changing our habits!

____________________________________________________________________________________________________________________________________________

PLUG & DRIVE

A key player in engineering for 60 years on the French market, BIBUS France specializes in hydraulics, pneumatics, mechatronics, environmental technology and system components.

Our "Plug & Drive" approach, aimed at Off-Highway machine manufacturers, enables you to benefit from innovative ready-to-use technical solutions !

____________________________________________________________________________________________________________________________________________

ACE Controls - Choosing the right MC shock absorber

ACE Controls' MC line features an impressive repertoire of dampers designed to deliver unrivalled performance in a variety of applications. From the most delicate miniature machines to extreme temperature requirements, this comprehensive range of products promises to meet the challenges of motion control with finesse.

____________________________________________________________________________________________________________________________________________

The importance of stainless steel against corrosion

Corrosion resistance, that is, the ability to resist degradation caused by the environment, is essential for many industries.

The role of ACE Controls stainless steel components goes far beyond mere functionality. Each product is designed not only to resist corrosive elements, but also to enhance overall performance and safety.

____________________________________________________________________________________________________________________________________________

Faced with obsolescence and shortage, BIBUS France reinvents MCO !

In an industrial world where obsolescence and scarcity have become growing challenges, maintaining systems in operational condition (MOC) has become increasingly complex.

These phenomena impact both technical and logistical support, leading to loss of efficiency or system unavailability.

____________________________________________________________________________________________________________________________________________

BIBUS AG : 75 years of innovation and excellence

Before becoming a major player in industrial innovation, the BIBUS AG Group was a small family business. Thanks to its ambition and values, cutting-edge technologies have become accessible to local and international companies.

Since its origins, the Group has been building trust and bringing manufacturers and companies closer together, with a benevolent vision of democratizing innovation.

How have its vision and missions made the BIBUS AG Group a privileged partner for automakers and manufacturers ?

____________________________________________________________________________________________________________________________________________

High-quality absolute position encoders from Netzer

Since 1998, Netzer has been designing and manufacturing high-quality absolute position encoders based on the unique Electric Encoder™ technology.

Their portfolio includes rotary encoders for a variety of applications...

____________________________________________________________________________________________________________________________________________

4 ways to protect your equipment with ACE shock absorbers (And What Can Happen If You Don’t)

Emergency Stop Systems are critical safety mechanisms designed to quickly halt machinery in dangerous situations, preventing accidents and protecting your workers.

____________________________________________________________________________________________________________________________________________

The efficiency of ACE damping technology

ACE Stoßdämpfer GmbH, world leader in damping technology in terms of quality and service, offers a complete range of innovative solutions to make your production processes more efficient and sustainable.

____________________________________________________________________________________________________________________________________________

How to reduce energy consumption in industry?

Both ecological and economic, the issue of reducing energy consumption concerns all industries.

Effective solutions can help companies rationalize their consumption while optimizing industrial processes.

____________________________________________________________________________________________________________________________________________

Re-industrialisation: "France is facing an enormous moment of opportunity"

France is at a strategic crossroads.

Are we ready to capitalise on #reindustrialisation opportunities

while facing up to our challenges?

____________________________________________________________________________________________________________________________________________

Stabilizing the hands of Parkinson’s patients: A collaborative journey between STIL and ACE

Development of a specialized orthosis to combat tremors.

10 million people worldwide suffer from Parkinson's disease, which affects more than 5.8% of the population over the age of 65.

____________________________________________________________________________________________________________________________________________

Corporate Social Responsibility

In 2017, one of our key account customers in the Defense sector asked us to provide him with our latest Ecovadis CSR assessment. This was the prerequisite for any collaboration between us...

Social responsibility has always been at the heart of our concerns, but we are a SME and we had not written or measured anything at the time. Nothing was formalized. We have launched!

____________________________________________________________________________________________________________________________________________

Origins of Flashcode

The linear barcodes that we have known for more than fifty years are doomed to disappear.

More and more obsolete, new consumer uses and new regulations replace them in favor of Flashcodes.

Do you know the origins of Flashcode?

This little square filled with black and white dots is now everywhere: in adverts, on business cards, on supermarket products, and so on. But did you know that the history of Flashcode goes back to the 90s, when a Japanese engineer had the idea of creating a two-dimensional barcode to store more information?

____________________________________________________________________________________________________________________________________________

Customize your industrial equipment to optimize production

To remain competitive, companies need to innovate, diversify, be flexible and optimize their costs. In 2022, 68% of BIBUS France customers saw their business grow thanks to the modernization of their production tools.

Customization of industrial equipment is a key solution for staying competitive and meeting the two major challenges of the industry of the future: flexibility and reducing the drudgery of tasks.

Let's discover the innovative solutions that help optimize machines and production processes.

____________________________________________________________________________________________________________________________________________

The feminization of industry, a performance factor

Industry 4.0 is a high-performance, competitive industry, but it's also an inclusive industry with greater equity and equality.

Changing the way women see industry is just as important as changing the way industry sees women. To meet this major challenge, a number of levers are being put in place: encouraging diversity in technical and engineering fields, offering women training to work with industrial tools, and deploying automated and robotized equipment to reduce the arduousness of tasks.

How does the feminization of production positions contribute to the performance and competitiveness of the industrial sector?

____________________________________________________________________________________________________________________________________________

Go beyond "make-or-buy" by combining internal and external innovation

Developing internally, buying a solution or collaborating with external partners to develop it is the first question that comes up when faced with an innovation need.

But for SMEs and SMIs that don't have the human and financial resources to invest in R&D and complex processes, outsourcing innovation can be a cost-effective and highly efficient solution.

____________________________________________________________________________________________________________________________________________

Omron Microscan Barcode Verifiers: optimal readability

Designed to check the legibility and compliance of engraved or printed barcodes, the barcode verifiers check various types of linear, two-dimensional and stacked linear combinations.

Featuring a camera, software and precision lighting, they are made of high-performance materials that ensure optimal barcode readability and traceability.

With evolving standards, how do these barcode verifiers contribute to the traceability of tomorrow's industry?

____________________________________________________________________________________________________________________________________________

3D drawings of Bansbach Easylift® cylinders

Download of 3D drawings of Bansbach easylift® gas springs

For production line managers, design engineers and all potential users, BIBUS France offers on its website the download of 3D drawings of Bansbach easylift® gas springs.

____________________________________________________________________________________________________________________________________________

Towards more sustainable industrial practices through technology

The industries that recognize that they have the most impact on the environment are the ones that are taking the most steps to develop more sustainable practices.

Constrained by a legislative framework, companies must increasingly integrate sustainability values into their strategy.

And in the ecological transition, the agricultural industry has a key role to play. Increasingly aware and constrained, it is adopting new, more sustainable practices and entering a new era through technological innovation.

How is the rise of new farming tools helping this industry reduce its environmental impact?

____________________________________________________________________________________________________________________________________________

La mécatronique dans l’industrie : une technologie incontournable aux nombreux avantages ?

Elle est discrète et pourtant étonnante. On l’actionne sans le savoir au quotidien et pourtant on ne la voit pas : la mécatronique.

La mécatronique est une technologie qui prend en compte la dynamique et les mouvements des objets pour devenir une solution intelligente qui s’accorde à tous les systèmes mécaniques.

BIBUS France propose des solutions mécatroniques pour assister au quotidien les opérateurs effectuant des mouvements de poussée ou de traction. Les outils de production peuvent être équipés de vérins à gaz, électriques, hydrauliques ou encore de roues électriques pour réduire les efforts.

Avec le concours de Frédéric Comte, Directeur général de BIBUS France, découvrez les avantages et les multiples applications de la mécatronique.

____________________________________________________________________________________________________________________________________________

Electric drive motors: finding alternatives to polluting combustion engines

France is one of the main emitters of CO2 in Europe, a gas that contributes to nearly 75% of greenhouse gas emissions.

We know that a large part of CO2 emissions come from vehicles equipped with hydraulic drive motors or thermal engines.

For example, the agricultural sector alone accounts for approximately 11 Mt of CO2 eq directly related to energy consumption by agricultural and forestry machinery. The figures are alarming and staggering and as a result, companies are innovating to find less polluting and more environmentally friendly solutions.

This is the case of BIBUS France, one of whose commitments to companies is the adaptation to new environmental constraints. In association with manufacturers such as I&W, BIBUS France offers innovative solutions that meet increasingly demanding business constraints in terms of respect for the environment, reduction of noise pollution and problems of ergonomics and use of consumables (e.g. fuel).

____________________________________________________________________________________________________________________________________________

New: Collaborative robot lease programme

Lease a collaborative robot from 5€ per hour.

This is now possible thanks to our brand new cobot rental programme.

Don't wait any longer to discover our financing solution!

____________________________________________________________________________________________________________________________________________

New: The mobile robot HD-1500

Expand your possibilities for autonomous material transport with the new mobile robot HD-1500.

With a heavy load capacity of up to 1500 kg, it proves to be ideal and adapted to the needs of today's plants that necessarily require a stand-alone material handling solution that can handle very demanding industrial automation tasks while implementing the new social distancing requirements due to the Covid-19 pandemic.

____________________________________________________________________________________________________________________________________________

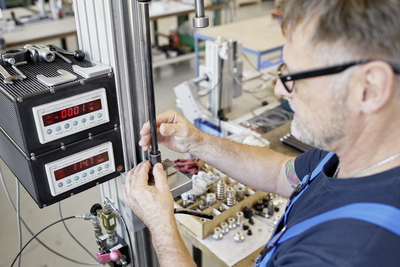

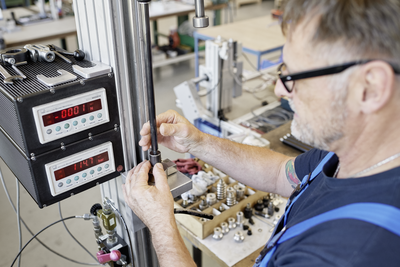

Customer case study: Making machine behaviour more reliable

"The movement of the ultrasonic welding head was not linearized, resulting in a large volume of non-conforming parts".

Find out by what means and tools we managed to reduce the number of non-conforming parts, and thus ensure the safety and reliability of our customer's production.

____________________________________________________________________________________________________________________________________________

Customer case study: Reducing operator thrust efforts and increasing flows in complete safety

"The arduousness is not proportional to the distance to be covered".

Find out how we optimized the travel time of this customer's trucks while reducing the drudgery for the operators through this experience.

____________________________________________________________________________________________________________________________________________

Supply failure : How to improve performance ?

Irène FOGLIERINI underlines here several important points that can make a business, a collaboration, a success or a failure if the people involved do not have the right level of information.

First of all, work on a forecast is nowadays essential even if the exercise may seem complicated. Why? The lead times for the supply of raw materials or primary parts (foundry, injection, etc.) have an unfortunate tendency to increase.

____________________________________________________________________________________________________________________________________________

1 - 2