These products are intended for professionals and cannot be sold to individuals.

Jäger Cleartec® range

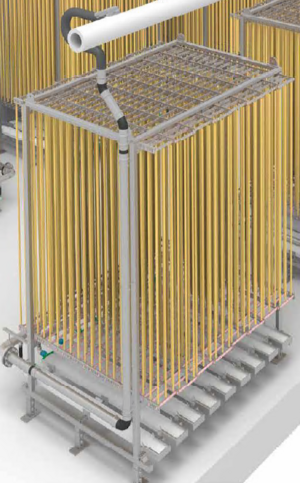

Cleartec® Biotextil

Cleartec® Biotextil is textile growth media for microorganisms and is installed to modernize or improve municipal and industrial wastewater treatment plants.

In addition, it is used as a space-saving biological treatment or as an on-site pre-treatment of industrial wastewater. The increased power allows a very compact design for new constructions of wastewater treatment plants.

Its flexibility, large structure, large active surface area and high resistance to specific wastewater chemicals make it an excellent material to support biological activity in wastewater treatment plants.

Biological wastewater treatment with combined system

Biotextile is applied in the biological field, mainly in aerated basins. Wastewater must be mechanically pre-treated. It is recommended to use a thin rack with a maximum distance of 6 mm between the rods. In addition, a sand chamber, grease separator and settling tank should be provided. In most cases, a usual secondary clarifier is installed downstream.

Normally, the Cleartec® Biotextil system works as a combined system. This means that suspended biomass, such as activated sludge treatment, as well as biomass fixed on the biotextile, called sessile biomass, contributes to the cleaning capacity.

Advantages

- Structured growth media with large surfaceDSC01028

- Steady discharge value at very good BOD and nitrogen elimination

- Outstanding energy efficiency due to optimized flow

- No clogging due to flexible structure

- Possibility to check media and diffusers due to liftable supporting frames

- Acting jointly: suspended and sessile biomass

- Increase of performance at existing plants

- Relief of the secondary clarifier

- Reduction of investment and operation costs

Cleartec® BioCurlz

Cleartec® BioCurlz is used as a fixed platform completely immersed in the biological phase of a wastewater treatment plant. The three-dimensional structure of the lace provides a growth surface for active microorganisms without flow restrictions. By using fine bubble aeration to provide oxygen to microorganisms, a vertical flow is obtained.

The thickness of the biofilm will be regulated by the velocity of the air stream by removing the old microorganism and forming a new active biofilm. The amount of active microorganisms is compared to the 47 g of suspended biomass per m of BioCurlz under optimal operating conditions.

The activity of microorganisms depends on the age of the sludge and differs according to the operating conditions of the plant. The basis of the Cleartec® BioCurlz installation is the evacuation of domestic water or compared to that at temperatures between +5°C and +36°C (+41°F and +97°F). The discharge of industrial waste water has been regulated separately. This also applies to other installations and areas of application.