|

Clamping Elements, ACE LOCKED Series.

Clamping elements from the LOCKED series also serve the purpose of safety. These ACE products clamp anddecelerate loads and are suitable for perfectly controlled holding, both linear and rotary, in all processes. Alongside ACE LOCKED solutions for conventional rail, rod or rotation clamping, special clamps with safety function for Z-axes, which reliably help secure axes with a gravitational load, are available in the LOCKED LZ-P series.

Advantages of using clamping elements

Increased process reliability

Available as clamping and emergency stop brakes

Very short stop distances

Very high clamping forces

Compact designs

Ideal for all standard sizes

The different models of clamping elements

LOCKED PL

Always on the safe side: The process clamping elements from the LOCKED series PL clamp directly onto the clear area of guide rails on linear modules with forces of up to 10,000 N. They are individually adjusted to the linear guide being used and are available for all rail sizes from 20 to 65 mm and profi les from all renowned manufacturers. This series achieves 100 % clamping force even on greased rails, due to the steel pads that are used. It offers optimum static clamping with up to1 million cyclesor up to 500 emergency braking operations. These process clamping elements also impress with their low system costs in comparison with hydraulic and electric solutions. The various models from the LOCKED Series PL from ACE are mainly used on machine tools and customised machines.

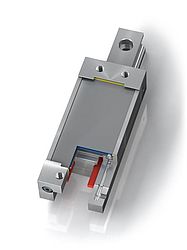

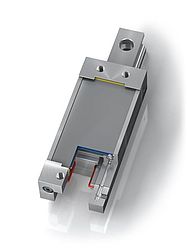

LOCKED PLK

Small can clamp perfectly too: The LOCKED Series PLK clamping elements are more compact than the Series PL components. They also clamp directly onto the respective linear guide, suit all standard rail sizes from 15 to 55 mm and profiles from the known suppliers and are extremely reliable and space-saving. Thanks to the patented spring steel plate system, the LOCKED-Series PLK achieves clamping and holding forces of up to 2 100 Nwith the shortest reaction times when vented. The LOCKED-Series PLK achieves 100 % clamping force due to the steel pads that are used, even on greased rails. The clamping elements represent the maximum holding forces. Whether in the 4 or 6 bar version, they are good for up to 1 million cycles or up to 500 emergency braking operations. Representatives of the LOCKED-Series PLK from ACE are primarily used in mechanical engineering and customised machines.

LOCKED SL

Always on the safe side: The safety clamping elements from the LOCKED series SL clamp and brake directly on the clear area of guide rails on linear modules with forces of up to 10 000 N. They are individually adjusted to the linear guide being used and are available for all rail sizes from 20 to 65 mm and profiles from all renowned manufacturers. Special brake pads made of low wear sintered metal are used for the additional emergency stop braking functions in safety clamping elements from the LOCKED series SL. The SL series offer optimum static clamping with a service life up to 1 million cyclesor up to 500 emergency braking operations. They also offer low system costs in comparison with hydraulic and electric solutions. The LOCKED-Series SL is particularly used in machinery and special purpose machines.

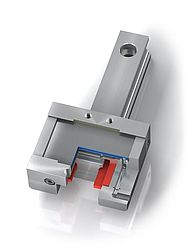

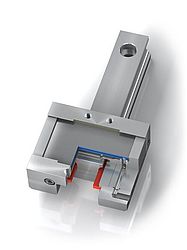

LOCKED SLK

Small can clamp perfectly too: The LOCKED Series SLK clamping elements are more compact than the Series SL. They also clamp directly onto the respective linear guide, suit all standard rail sizes from 15 to 55 mm and profiles from the known suppliers and are extremely reliable and safe. Thanks to the patented spring steel plate system, the Series SLK achieves clamping and holding forces of up to 2 100 N with the shortest reaction times when vented. Thanks to the sintered metal coatings and the clamping function in emergency stop (e.g. in case of a power failure), this range enables braking directly on the rail. All clamping elements offer the maximum holding and braking forces and achieve up to 1 million clamping cyclesor up to a maximum of 500 emergency braking operationsin the 4 and 6 bar version. The LOCKED-Series SLK are used in mechanical engineering and customised mechanical engineering.

LOCKED LZ-P

Innovative and BG certified: The pneumatic clamping elements from the LOCKED-Series LZ-P have been specially designed for safe, reliable clamping on the vertical or Z-axes. The wedge principle makes sure that the gravity loaded axis does not drop. The brake wedges are pushed on both sides against the flat parallel surfaces of the guide rail in case of a loss of pressure. Initially developed for Bosch-Rexroth rails in sizes 15 and 25 mm, a test certificate from the trade association was awarded after extensive tests on these clamping elements. Further certifications from other rail manufacturers and sizes are prepared and can be implemented within the shortest time. Users achieve holding forces of up to 2 500 N. Pneumatic clamping elements from the LOCKED-Series LZ-P are used in all sectors of modern mechanical engineering and customised machine tools.

LOCKED PN

Immediate clamping in case of loss of pneumatics: Suitable for rods with diameters of 20 to 40 mm, the clamping elements from the LOCKED-Series PN absorb the forces axially and rotationally. With holding forces of up to 36 000 N, they reach or exceed the levels of hydraulic clamps. The system costs are however lower. Alongside clamping in both directions of motion, the LOCKED-PN also surprises with its compact design. They need less installation space and enable short rod lengths. For versions with ISO pneumatic cylinders, the base plate is coordinated to the dimensions of the fl ange sizes of standard cylinders according to ISO 15552. Users appreciate the modular system. It allows several segments to be stacked so that the necessary clamping force can be attained for every application. The areas of application for the LOCKED Series PN are mechanical engineering and machine tools.

LOCKED PRK

Compact and safe: when space becomes restricted, the compact clamping elements from the LOCKED-Series PRK come into their own. As pneumatic rod clamping with low heights of 28 to 34 mm, they provide clamping forces of up to 5 000 N. Clamping is carried out by a diaphragm spring-plate system and is released when compressed air is applied. Clamping elements from the LOCKED-Series PRK absorb the forces on rods with diameters between 20 and 40 mm both axially and rotationally. The function makes them suitable for use as static clamping without pressure, because the failure or drop of pneumatic pressure triggers immediate clamping. High clamping forces with low system costs compared with hydraulic

and electric solutions make these clamping elements particularly interesting. Models from the LOCKED-Series PRK are used in mechanical engineering and customised machine tools.

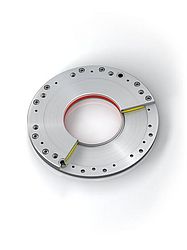

LOCKED R

Direct clamping on the shaft: Rotation motions are prevented by the LOCKED-Series R. Their clamping elements are available for shaft diameters of 50 to 340 mm and ensure maximum holding forces. The clamp is immediately applied by the diaphragm and spring-plate system when pressure is lost. Pneumatic quick-switch valves reduce the reaction times. The costs are low in comparison with hydraulic clamping systems. Their performance is, however, achieved or exceeded despite the compact and easy to assemble design. Special versions for YRT bearings as well as active clamping elements are additionally available. ACE recommends the use of the optional shaft flange as wear protection. The clamping force can be increased considerably by the use of the additional air function. Models from the LOCKED-Series R are also used in mechanical engineering and customised machine tools.