ACE - Miniature shock Absorbers

Miniature shock absorbers from ACE are hydraulic machine elements which permit to slow down quickly heavy loads without damages. This material is easily integrated in a structure thanks to its compactness, some models can be set up directly in pneumatics actuators. Miniature shock absorbers are used to develop the efficiency and reduce loads of existing products: handling devices, rotary and pivoting actuators, linear cylinders and many other industrial applications. The manufacturing of this shock absorber is carried out in only one piece composed in solid high tensile alloy. This matter combined with its sealing techniques offer a long service life.

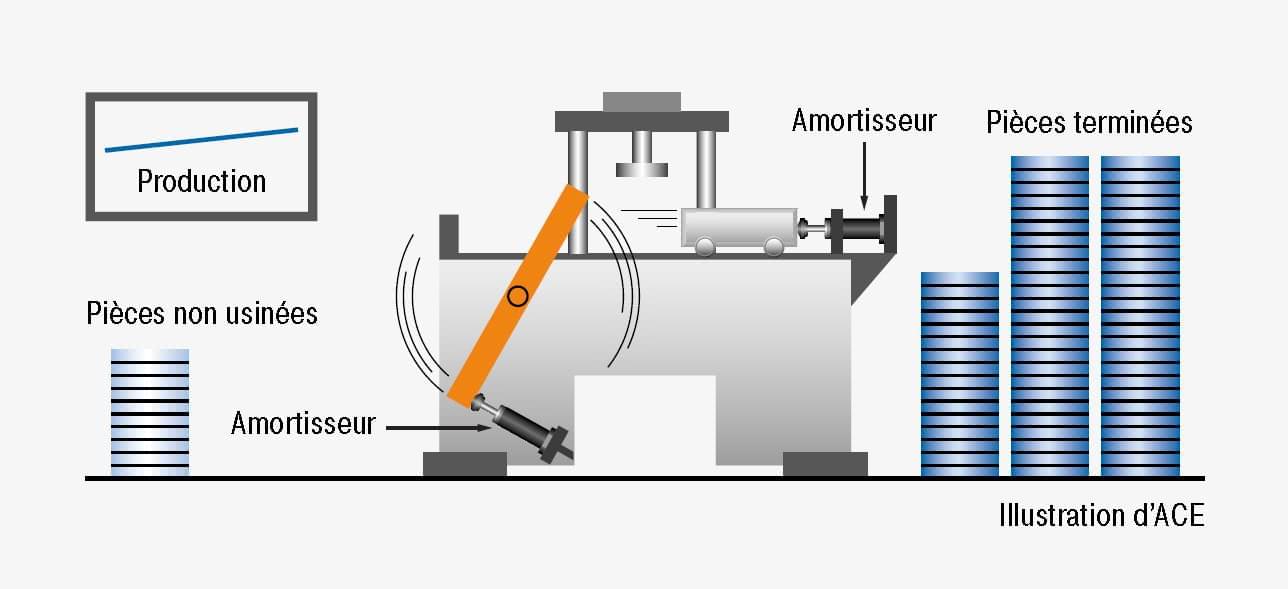

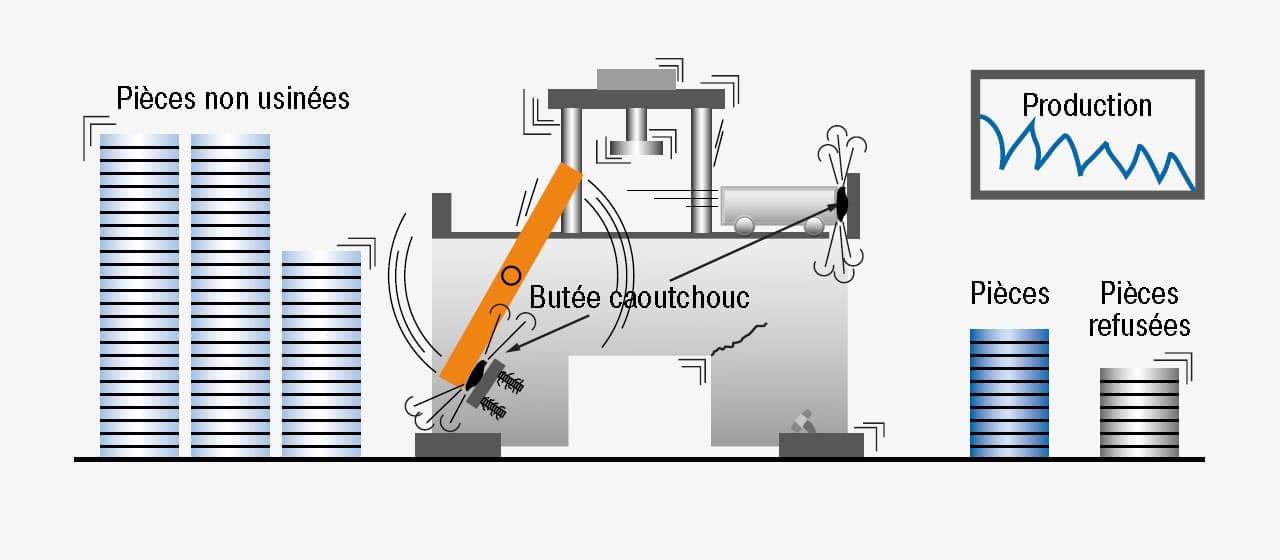

Stopping with Miniature Shock Absorbers | Stopping with Rubber Buffers, Springsd, Dashpots or Cylinder Cushions |

|  |

Your advantages using miniature shock absorber | Results using conventional dampers |

The different models of miniature shock absorbers

MC5 à MC75

Self-Compensating

Energy capacity 0.68 Nm/Cycle to 9 Nm/Cycle

Stroke 4 mm to 10 mm

The ACEminiature shock absorber MC5, MC9, MC10, MC25, MC30 and MC75 impresses users with their reduced dimensions and their very short overall lengths and low resetting forces after braking. The outer body of each damper, produced from one solid piece, are filled with temperature stable oil, offer a continuous thread incl. a supplied lock nut and also have an integrated positive stop. These hydraulic machine elements from ACE, are ready for immediate installation and are maintenance-free. A comprehensive range of energy absorption with a wide range of effective weight potential are further benefits in these miniature units. These miniature shock absorbers are perfectly suited to use in applications such as mechanical engineering, medical and electro-technology and robotics.

MC150 à MC600

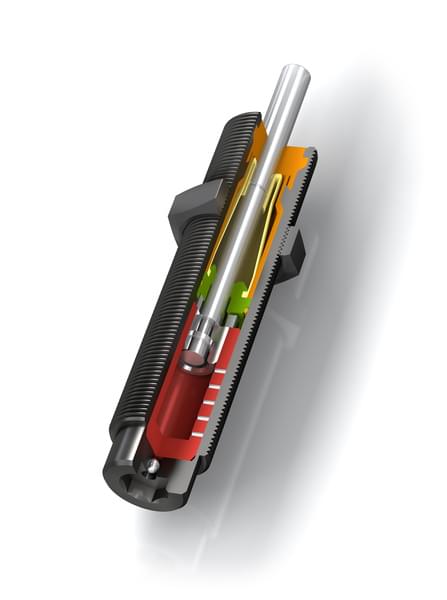

Self-Compensating, Rolling Diaphragm Technology

Energy capacity 20 Nm/Cycle to 136 Nm/Cycle

Stroke 12 mm bis 25 mm

The ACE miniature shock absorber MC150, MC225 and MC600 product family is suitable for an exceptional high lifetime of use with up to 25 million cycles, due to a hermetically sealed rolling diaphragm in each absorber. The rolling diaphragm technology perfected by ACE ensures complete separation of the damping fluid from the surrounding air. This makes direct installation in a pressure chamber e.g. as end stop damping in pneumatic cylinders up to approx. 7 bar possible. The rolling diaphragm also benefits the very low return forces of these maintenance-free, ready-to-install absorbers. Progressive energy capacities, with a wide range of effective weight potential make these miniature shock absorbers, complete with an integrated positive stop a winner. Furthermore, the use of a side load adapter allows impact angles of up to 25°. Miniature shock absorbers capable of universal mounting even inside a cylinder and also available in stainless steel options. They are often used in mechanical and plant engineering, and a multitude of other applications.

MC150-V4A à MC600-V4A

Self-Compensating, Stainless Steel, Rolling Diaphragm Technology

Self-Compensating, Stainless Steel, Rolling Diaphragm Technology

Energy capacity 20 Nm/Cycle to 136 Nm/Cycle

Stroke 12 mm to 25 mm

The ACE miniature shock absorber MC150V4A, MC225V4A and MC600V4A in stainless steel are based on the MC150 to MC600 product family and its proven damping technology. This means that these special absorbers offer all of the benefits of the MC standard units such as the proven ACE rolling diaphragm technology for maximum service life and direct installationin a pressure chamber with up to approx. 7 bar. Thanks to perfectly progressive maximum energy absorption and effective weight potential, their use is augmented even further by the outer body and a complete range of accessories made of stainless steel (material 1.4404). Miniature shock absorbers made of stainless steel are mainly used in medical and electro-technology, but also in shipbuilding, packaging and chemicals industry and in the food processing. For the latter, they are filled with a special oil in order to fulfil the authorisation conditions (NSF-H1) for this market.

PMCN150 à PMCN600

Self-Compensating, Rolling Diaphragm Technology, TPU Bellow

Energy capacity 20 Nm/Cycle to 136 Nm/Cycle

Stroke 12 mm to 25 mm

The ACE miniature shock absorbers PMCN150, PMCN225 and PMCN600 have a compact, perfectly sealed cap as a special feature. This protection bellows, made of TPU (thermoplastic polyurethane), safely encapsulates the proven ACE rolling diaphragm from the outside environment. Aggressive cutting, lubricating and cleaning agents don‘t stand a chance and the function of the maintenance-free, ready to-install shock absorber is retained. They are also available in full stainless steel. The PMCN series is a good alternative to the SP type air bleed collar if no compressed air is available on the machine or system. Reliable protection against aggressive fluids, these miniature shock absorbers are the first choice everywhere where conventional dampers wear out too quickly, eg. As in machining centers or other applications of mechanical engineering.

PMCN150-V4A à PMCN600-V4A

Self-Compensating, Rolling Diaphragm Technology, TPU Bellow

Self-Compensating, Rolling Diaphragm Technology, TPU Bellow

Energy capacity 20 Nm/Cycle to 136 Nm/Cycle

Stroke 12 mm to 25 mm

The ACE miniature shock absorbers PMCN150-V4A, PMCN225-V4A and PMCN600-V4A are also available in a stainless steel design. These are particular interest to the food and packaging industries. Their main special feature is the compact, totally sealed bellow between the body and the cap made of TPU (thermoplastic polyurethane). This protection safely encapsulates the ACE rolling diaphragm from the outside environment. Aggressive fluids don‘t stand a chance. The PMCN series is an excellent alternative if the accessory option of the SP type air bleed collar cannot be used due to a lack of compressed air. The PMCN series miniature shock absorbers, produced from stainless steel, are primarily suitable for use in the food industry, but are also wherever an elegant look is important e.g. in shipbuilding.

SC190 à SC925

Self-Compensating, Soft-Contact

Self-Compensating, Soft-Contact

Energy capacity 25 Nm/Cycle to 110 Nm/Cycle

Stroke 16 mm to 40 mm

The ACE miniature shock absorbers SC190, SC300, SC650 and SC925 manufactured from one solid piece are designed in such a way that they can be setup with a linear or a progressive braking curve. The soft damping character is thanks to the special, long strokes producing smooth deceleration and low reaction forces. These maintenance-free, ready-to-install hydraulic machine elements are equipped with an integrated positive stop. The use of side load adapter allows impact angles of up to 25°. Thanks to the designed overlapping effective weight ranges, these dampers cover an effective load range of below 1 kg to more than 2,000 kg. The miniature shock absorbers from the SC190 to 925 series are used in mechanical engineering and primarily in the areas of handling and automation.

SC²25 à SC²190

Self-Compensating, Piston Tube Technology

Self-Compensating, Piston Tube Technology

Energy capacity 10 Nm/Cycle to 31 Nm/Cycle

Stroke 8 mm to 12 mm

The ACE "soft contact" miniature shock absorbers SC²25, SC²75 et SC²190 extend from thread size M10 to M14 and cover effective weight ranges of 1 kg to 1,550 kg. All models are characterised by high energy absorption and they also unite the piston tube technology with the diaphragm seal perfected by ACE. This enables direct installation as end position damping in pneumatic cylinders at 5 to 7 bar or applications where deceleration needs to take placed close to the pivot point. They are maintenance-free, have an integrated positive stop and are mountable in any position. The option of a side load adapter allows impact angles of up to 25°. Thanks to their robust design and their durability, these miniature shock absorbers can be used for a wide range of applications. Designers mainly use them for pick and place systems, pneumatic rotary modules and in automation applications.

SC²300 à SC²650

Self-Compensating, Piston Tube Technology

Self-Compensating, Piston Tube Technology

Energy capacity 73 Nm/Cycle to 210 Nm/Cycle

Stroke 15 mm to 23 mm

The ACE larger "soft contact" miniature shock absorbers SC²300 to SC²650 are available with up to three times the energy absorption compared to similar sizes of standard shock absorbers SC190 to 925, due to the ACE piston tube specialty. Furthermore, the membrane accumulator serves as a compensation element for the oil displaced in the shock absorber and replaces the standard use of absorber materials. This increases process safety even further. The absorbers, which are perfect for rotary modules for example, are available in progressively stepped effective weight ranges with an integrated positive stop. They are maintenance-free and ready for direct installation. The side load adapter option allows impact angles of up to 25°. These miniature shock absorbers offer high performance levels with a long service life and are particularly popular for handling, mounting very close to pivots and automation tasks.

MA30 à MA900

Adjustable

Adjustable

Energy capacity 3.5 Nm/Cycle to 100 Nm/Cycle

Stroke 8 mm to 40 mm

The ACE miniature shock absorbers MA30, MA50, MA35, MA150, MA225, MA600 and MA900 can be adjusted and precisely adapted to your requirements. For example, the MA150 displays the rolling diaphragm technology from the MC150 to MC600 family and offers all of the advantages of this technology, such as use in pressure chambers. Thanks to long strokes (including 40 mm on the MA900) lower reaction forces result, which provide a soft damping characteristic. All variations of these units are maintenance free, ready-to-install machine elements and have an integrated positive stop. They provide the best service where application data changes, where the calculation parameters are not clear or where maximum flexibility in the possible usage is required. The adjustable miniature shock absorbers from ACE can be used to meet precisely the customer‘s application and are therefore found everywhere in mechanical engineering and many other applications.

Our fittings tips

How to adjust a shock absorber correctly ? | How to properly mount two shock absorbers in parallel ? |