Industrial shock absorbers

ACE provides the right industrial shock absorber for every application

Firstly, ACE's range of industrial shock absorbers contains more than 200 models available.

From the most compact (4 mm stroke) to the largest (406 mm stroke), there is a shock absorber for every complication. ACE shock absorbers are also available in self-compensating or adjustable versions.

In addition, they can absorb an energy per cycle of between 0.68 Nm and 126,500 Nm. This allows you to slow down effective masses between 500 g and 204 t with very high precision.

Differences between a conventional shock absorber and an industrial shock absorber

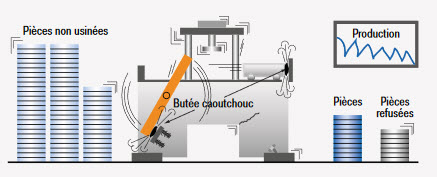

Braking without industrial shock absorber

(Rubber, springs, hydraulic brakes or cylinder damping)

- Results of the use of conventional shock absorbers

- Loss of production

- Damage to machinery

- Increased maintenance costs

- Higher operating noise

- Oversized constructions

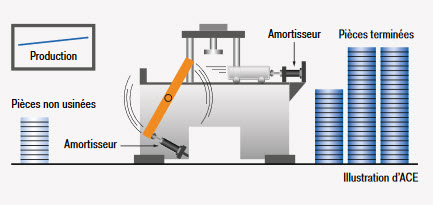

Braking with ACE industrial shock absorber

- Results of the use of industrial shock absorbers

- Safe and reliable production

- Long machine life

- Simple and economical construction

- Low operating costs

- Quiet and economical machines

- Less stress on the machine

- Increased profitability

The different models of industrial shock absorbers MAGNUM range

ACE industrial shock absorber means moving loads are evenly decelerated over the full stroke. The result: the lowest braking force and shortest braking time. The MAGNUM series from ACE is viewed as the reference standard for medium design sizes in damping technology.

Innovations such as diaphragm accumulators, seals, tube-shaped inner pressure chambers and many more make a decisive contribution towards extension of the service life. This means that the effective load range can be extended considerably, which provides users with more scope with respect to the absorber size and utilisation of the machine‘s output.

ACE offers a wide range of matching accessories for this and all other absorber series. This eliminates internal production of assembly parts, which involves high costs and lots of time.

Shock asborber MC33 to MC64

- Self-Compensating

- Energy capacity 170 Nm/Cycle to 5,650 Nm/Cycle

- Stroke 23.1 mm to 150 mm

The range of ACE industrial shock absorber MC33, MC45 and MC64 is so successfull thanks to the combination of the latest sealing technology, annealed guide bearing and integrated positiv stop. After all, users benefit from the longer service life of the products, even in the most difficult environments. High energy absorption in a compact design and a wide damping range lead to huge advantages in practice. Alongside generally more compact designs, these small yet very powerful absorbers enable full use of the machine‘s performance. These self-compensating industrial shock absorbers are used in all areas of mechanical engineering – especially in automation and for gantries.

Shock asborber MC33-V4A to MC64-V4A

- Self-Compensating, stainless Steel

- Energy capacity 170 Nm/Cycle to 3,730 Nm/Cycle

- Stroke 23.1 mm to 99.4 mm

The ACEself-compensating insdustrial shock absorbers MC33-V4A, MC45-V4A et MC64-V4A are also available with all outer components made from stainless steel, material 1.4404 (except piston rod). They are filled in the factory with special oil, which meets the permit conditions (NSF-H1) for the food industry. Just like the standard product family, the MAGNUM stainless steel models are distinguished by their robust, modern sealing technology, high energy absorption in a compact design, integrated positive stop and a wide damping range. Equipped with a PU head, they are available in thread sizes M33x1.5 to M64x2 with damping strokes up to 100 mm. These self-compensating industrial shock absorbers made of stainless steel from ACE are mainly used in the food, medical, electro and offshore industries, but also in many other markets.

Shock asborber MC33-HT to MC64-HT

- Self-Compensating, use at 0 °C to 150 °C

- Energy capacity 170 Nm/Cycle to 3,730 Nm/Cycle

- Stroke 23.1 mm to 99.4 mm

The HT industrial shock absorbers (High Temperatures) MC33-HT, MC45-HT et MC64-HT are characterised by the use of special seals and fluids. This means that these versions can even be used at extreme temperatures of 0 °C to 150 °C in order to safely and reliably damp masses and take away 100 % kinetic energy.

Additional benefits are their robust, innovative sealing technology, high energy absorption in a compact design, fixed positive stop and a wide damping range.

Shock asborber MC33-LT to MC64-LT

- Self-Compensating, use at -50 °C to +66 °C

- Energy capacity 170 Nm/Cycle to 5,650 Nm/Cycle

- Stroke 23.1 mm to 150 mm

The LT industrial shock absorbers (low temperature) MC33-LT, MC45-LT and MC64-LT are characterised by the use of special seals and fluids. This means that these versions can even be used at extreme temperatures of -50 °C to +66 °C in order to safely and reliable damp masses. Like the range MC33 to MC64, the LT industrial shock absorbers have the same characteristics : robust, innovative sealing technology, high energy absorption in a compact design, fixed positive stop and a wide damping range.

Shock asborber SC33 to SC45

- Self-Compensating, Piston Tube Technology

- Energy capacity 155 Nm/Cycle to 680 Nm/Cycle

- Stroke 23.1 mm to 48.6 mm

The industrial shock absorber SC33 to SC45 are so strong and durable, thanks to the combination of proven sealing technology from the MAGNUM range including membrane accumulator with the well-known piston tube technology. Short stroke lengths of 25 mm to 50 mm lead to shorter braking times in combination with a high energy absorption. In comparison with other models, the SC industrial shock absorber have a high oil volume, which ensures the maximum effective weights. These dampers safely and reliably decelerate rotary movements without unwanted recoil effects. They are used in pivot units, rotary tables, robot arms or integrated else where in construction designs.

Shock asborber MA/ML33 to MA/ML64

- Adjustable

- Energy capacity 170 Nm/Cycle to 6,780 Nm/Cycle

- Stroke 23.1 mm to 150 mm

The industrial shock absorberMA/ML33, MA/ML45 and MA/ML64 can be precisely adjusted both at the front and rear, also contribute towards the success of the MAGNUM series. Equipped with excellent sealing technology, an annealed guide bearing and integrated positive stop, they are robust and durable.

These dampers absorb 50 % more energy than their predecessors but are built even more compactly. This makes the ML series especially suitable for effective loads of 300 kg to 500,000 kg. Where work is done with changing application data and wherever flexibility is required, they make the best option.

These adjustable industrial shock absorbers are used in all areas of mechanical engineering in automation, integrated in linear carriages or pivoting units and also for gantries.

Easily mount a shock absorber

How to adjust a shock absorber correctly ? | How to properly mount two shock absorbers in parallel ? |